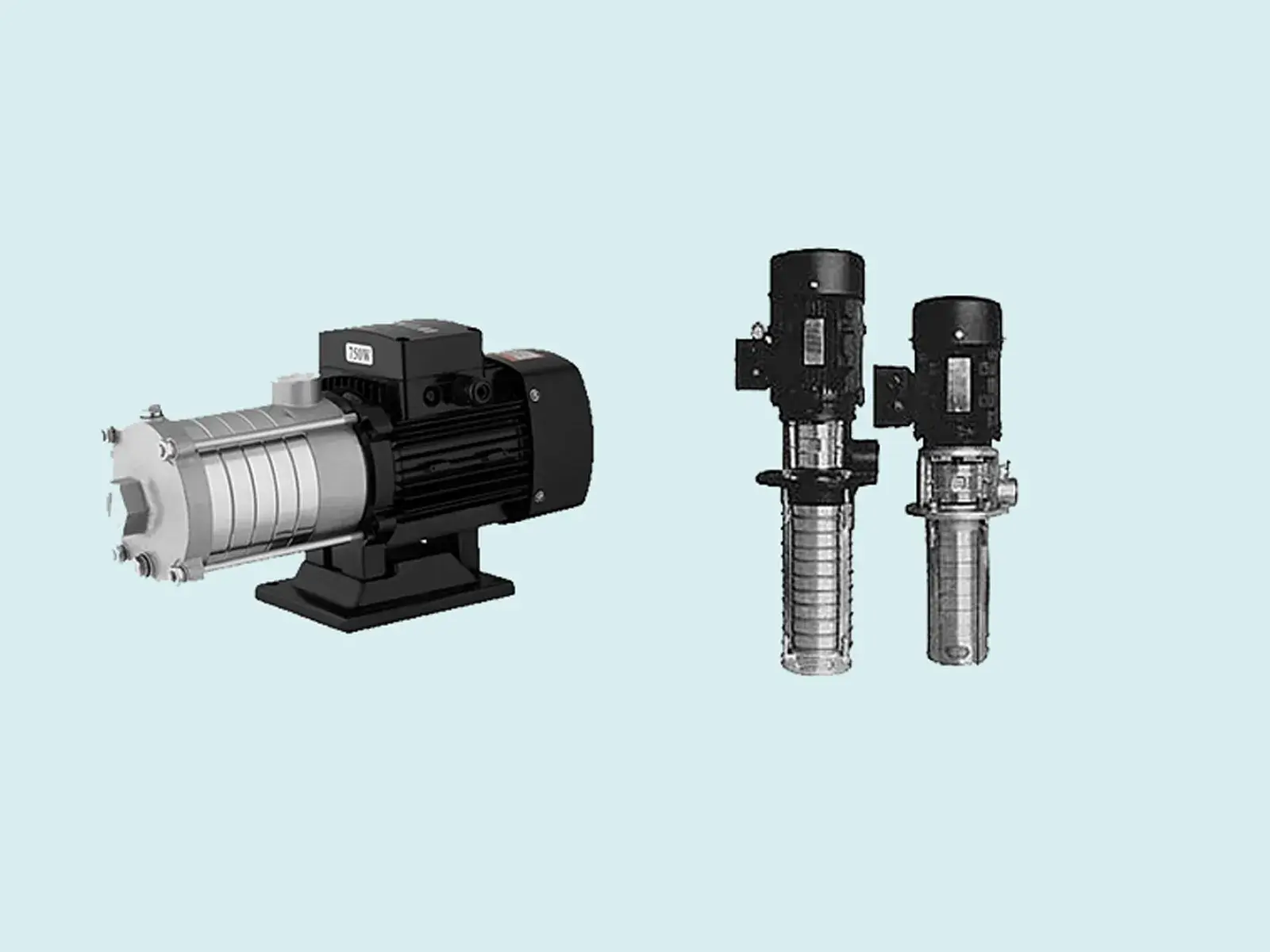

High-pressure pumps hold an essential status at manufacturing sites, oil and gas operations, agricultural activities, and water treatment facilities. Their core functions include cleaning operations, waterjet cutting applications, and fluid transport duties.

Maintaining the safety and optimal performance of high-pressure pumps must remain a top priority, considering their exceptional operational pressure levels. Correct use and adequate maintenance ensure performance stability while preventing costly downtime and hazardous incidents. Here are some tips for high-pressure pump safety and performance:

Ensure the pump matches operational requirements.

The foundation starts with choosing the correct pump that suits the intended application. Each application utilizing pumps must operate with precise flow rate controls, specific pressure rating configurations, and compatible material selection. Operating a pump at higher flow rates than its power level permits can create an unsafe pressure environment that destroys the system prematurely.

Ensure proper installationSeveralf safety problems can stem from the wrong equipment assembly during installation. Keep the pump fixed to a firm base surface that reduces potential vibrations when operating. All pressure lines, including hoses and pipes, should have proper fittings to create secure connections that prevent leaks and blowouts during high-pressure operations.

Manufacturers like Pumpbiz provide specific guidelines to establish proper alignment between the pump and motor units. Operators should follow these guidelines to protect the integrity of their equipment.

Conduct regular maintenance and inspections.

The performance and operational lifetime of high-pressure pumps depend entirely on routine maintenance practices. A regular inspection schedule should cover all components, including seals, valves, and gaskets. Check for signs of mechanical deterioration and search for indications of leaks and corrosion.

Pump performance remains optimal when operators perform regular cleaning tasks that eliminate performance-blocking debris and dirt. Following manufacturer guidelines and applying recommended lubrication to moving parts prevents overheating and limits excessive wear.

Track pressure parameters

High-pressure pumps must operate at their designated pressure and flow. Gauges and sensors are important for tracking these pressure parameters in real-time.

Keep in mind that equipment failure and safety hazards occur when pressure exceeds the safety guidelines, thus resulting in burst pipes or fittings. A pressure relief valve should be installed to avoid over-pressurization when spikes occur regularly.

Train operators on safe usage

Operating high-pressure pumps requires essential training for all personnel. Workers performing tasks close to high-pressure systems must always wear personal protective equipment (PPE). Educate operators about the safety perils of improper pump usage, particularly its effects on human safety and equipment breakdown.

Use a quality replacement part.s

Whenever the pump demands replacements, use superior-quality replacement parts from established suppliers. Substandard parts degrade safety parameters and the operational performance of the pump system, leading to recurring machine breakdowns and unsafe situations. When you choose reliable parts suppliers, your operation will have peak efficiency and lower safety risks.

The takeaway

The safety and performance of high-pressure pumps depend on correct installation, regular maintenance routines, and operator education. The right maintenance procedures guarantee that your high-pressure pumps function effectively and safely for many years.